About Alexandria

Metal Finishers

Quality Metal Finishing

Since 1962

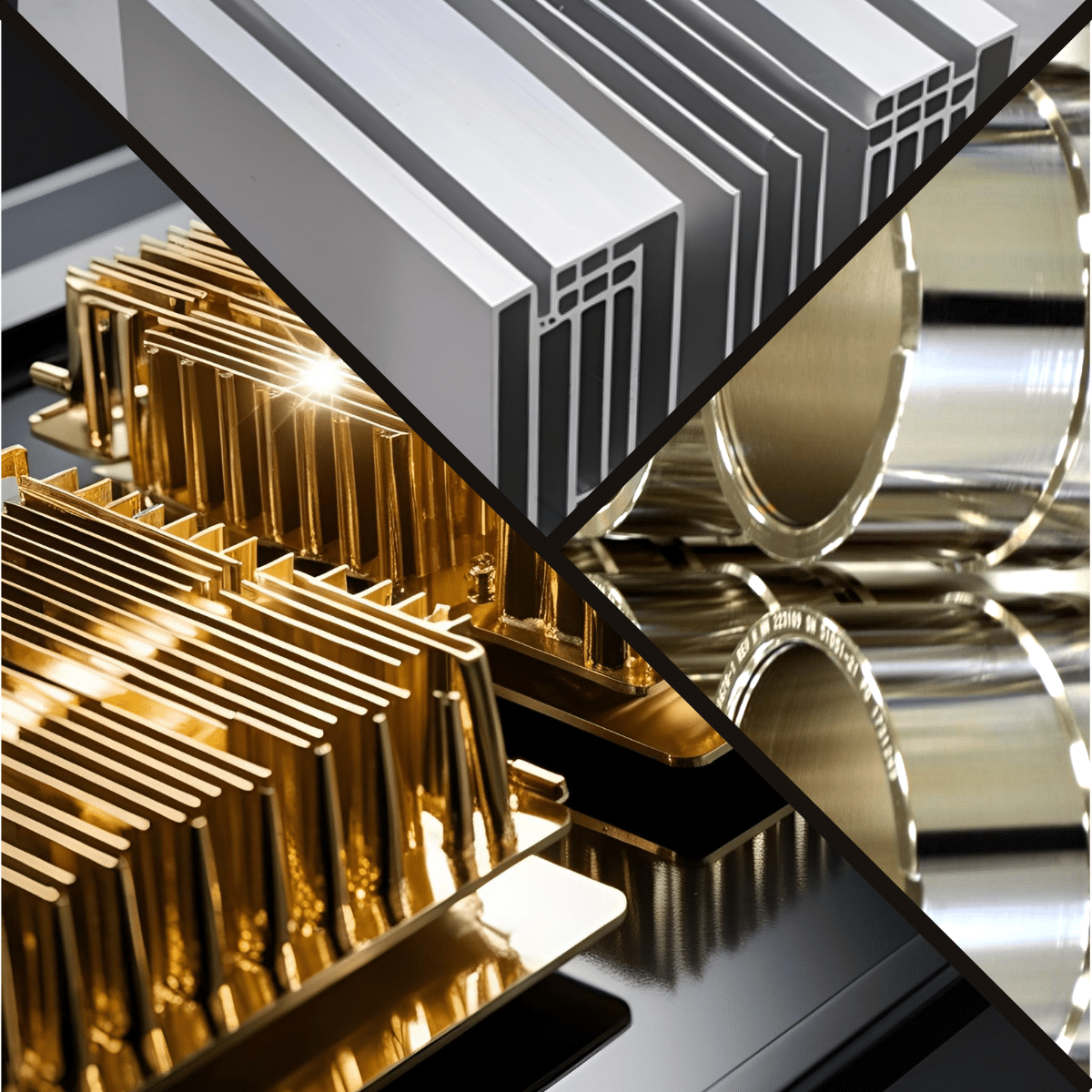

Alexandria Metal Finishers was founded in 1962 to meet the demanding electroplating and anodizing requirements of our country’s space program in the field of metal finishing. The company provides metal finishing services to aerospace, telecommunications, electronics, medical, packaging, defense and commercial industries.

Specializing in technically difficult and unique plating and finishing processes, Alexandria Metal Finishers has built a national reputation for quality and reliability while maintaining its concern for the environment.

From precious metal plating (gold, silver, & rhodium) to hard anodizing and multi-plating on unusual alloys and special set-ups, Alexandria Metal Finishers provides a diverse range of finishing services. Currently offering more than 40 processes including non-destructive testing, we also maintain an in-house library of federal, aerospace, military and commercial standards.

Currently Offering Over

40 Processes

Alexandria Metal Finishers’ 40,000 square foot facility houses processing equipment designed to provide a wide range of anodizing, plating, and other metal finishing services. This facility also includes a complete laboratory with state-of-the-art test equipment to provide the advanced technical capabilities, testing, documentation, and traceability required to ensure the highest quality standards. We have achieved registration to ISO 9001 and have received quality awards from many of the major government contractors including NASA, ATK, Aerojet, Lockheed, Northrop, and Honeywell.

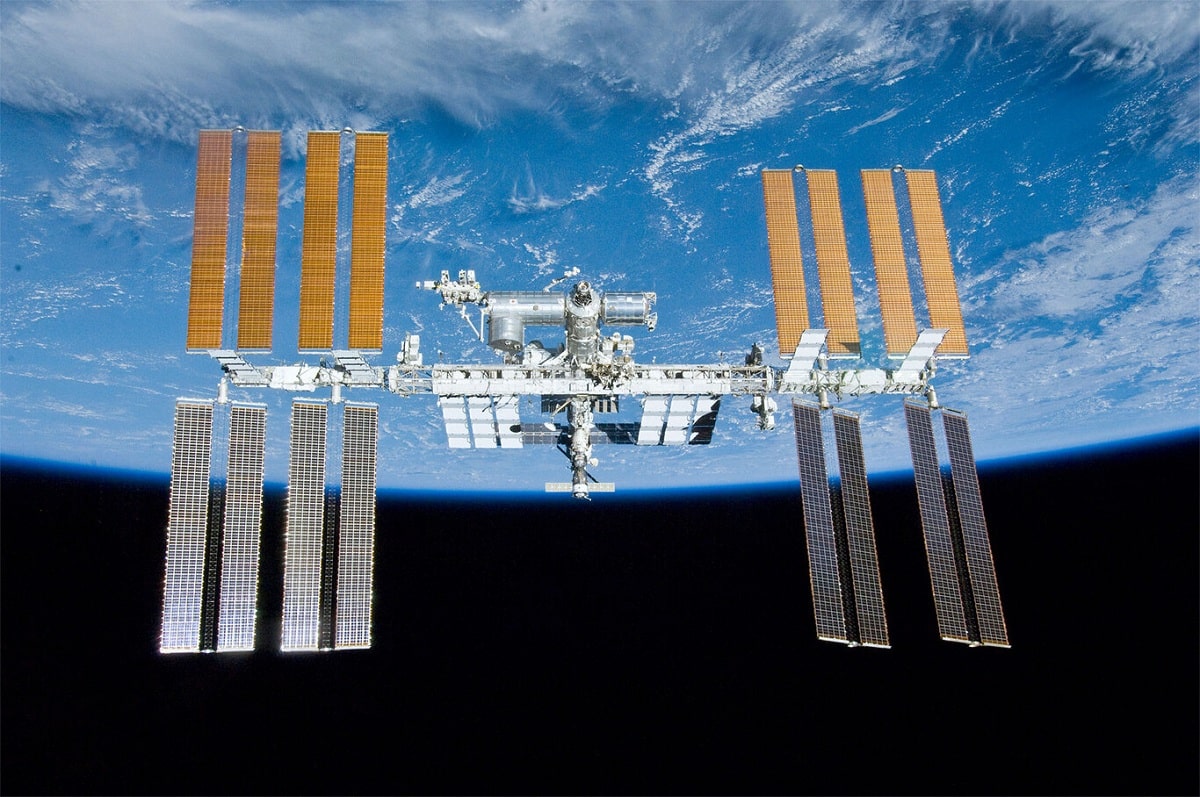

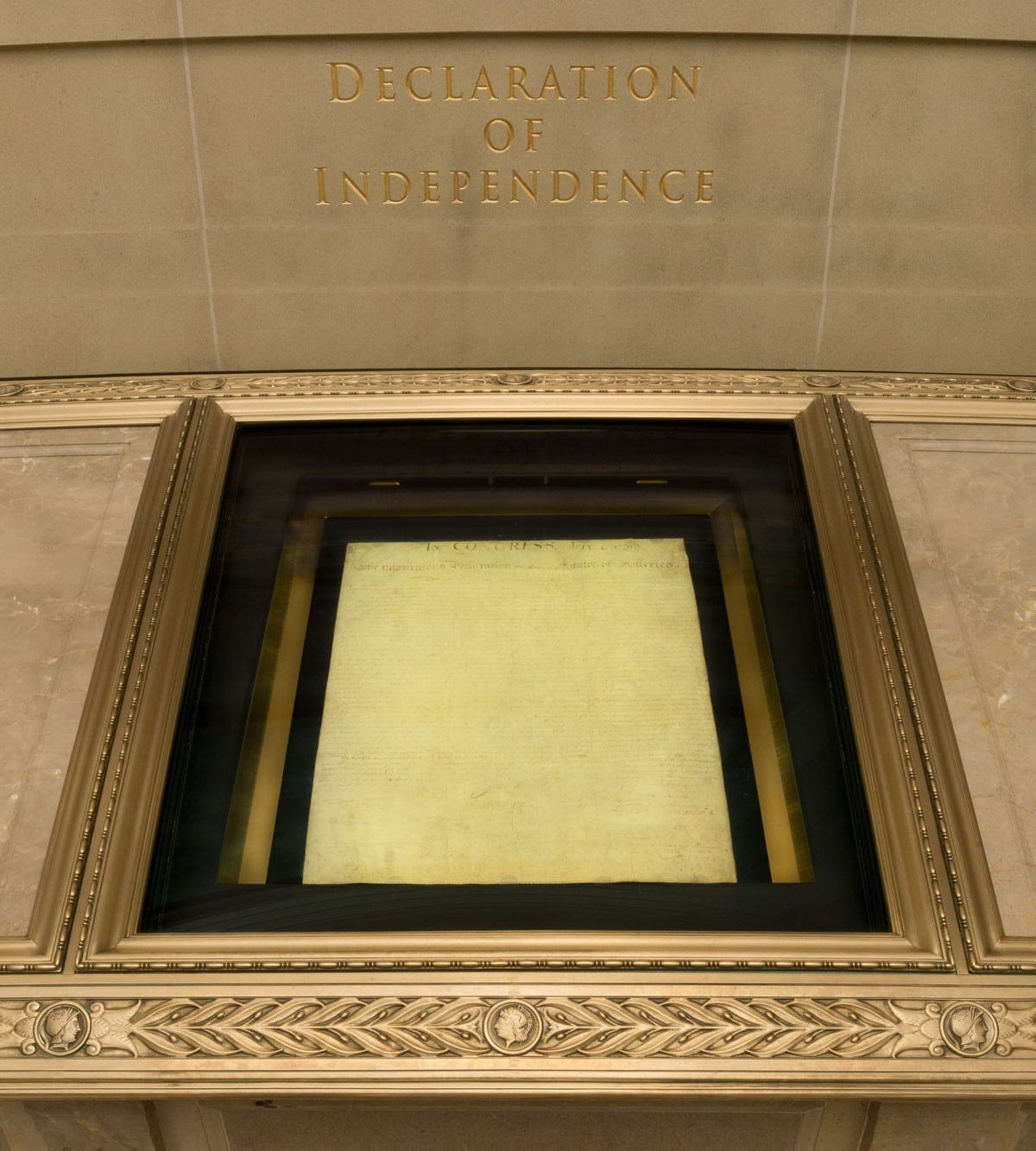

Over its 60 year history, Alexandria Metal Finishers has been involved in a wide range of special projects – many involving research & development and special set-ups. These special projects have included finishing for the Peacekeeper Program, the Titan Missile, the International Space Station, the Stinger Missile, the NASA wind tunnel, the Washington Monument Restoration project, and the re-encasement of the Charters of Freedom for the National Archives and Records Administration.

Milestones

1962-1984

Alexandria Metal Finishers was started in a small retail shop next to the movie theater in Old Town Alexandria, Virginia in 1962.

In 1965, the company moved to a larger location in an industrial space nearby. New finishes as well as a larger capacity were added and the company began working on aerospace projects.

1985

Alexandria Metal Finishers designed and constructed a 45,000 square foot plating, anodizing, chemical finishing facility and moved operations from Alexandria to Lorton, Virginia.

1988-1989

Alexandria Metal Finishers was chosen by Hercules in Utah to hard anodize the large mandrels (10′ diameter, 8′ high) required to construct the Titan Missiles.

1996 & 2017

Alexandria Metal Finishers was selected by Honeywell to gold plate components required for the construction of the International Space Station in 1996 and again in 2017.

1998-1999

During the 1998 Washington Monument refurbishment, its 1934 lightning rod assembly was removed, disassembled, and sent to Alexandria Metal Finishers. Sections up to 30 feet long were meticulously cleaned, re-electroplated with pure gold, and returned to the monument’s peak to continue safeguarding this iconic landmark.

2000-2003

NARA and NIST partnered to redesign the encasements protecting the United States’ founding documents, known as the Charters of Freedom: the Declaration of Independence, the Bill of Rights, and the Constitution, displayed in the National Archives Rotunda. Alexandria Metal Finishers proudly contributed to this historic project by providing plating and anodizing for the new encasements.

2019

National Aerospace Defense Contractor Accreditation Program (Nadcap) Accreditation achieved for both Aerospace Quality System and for Chemical Processing.

2023

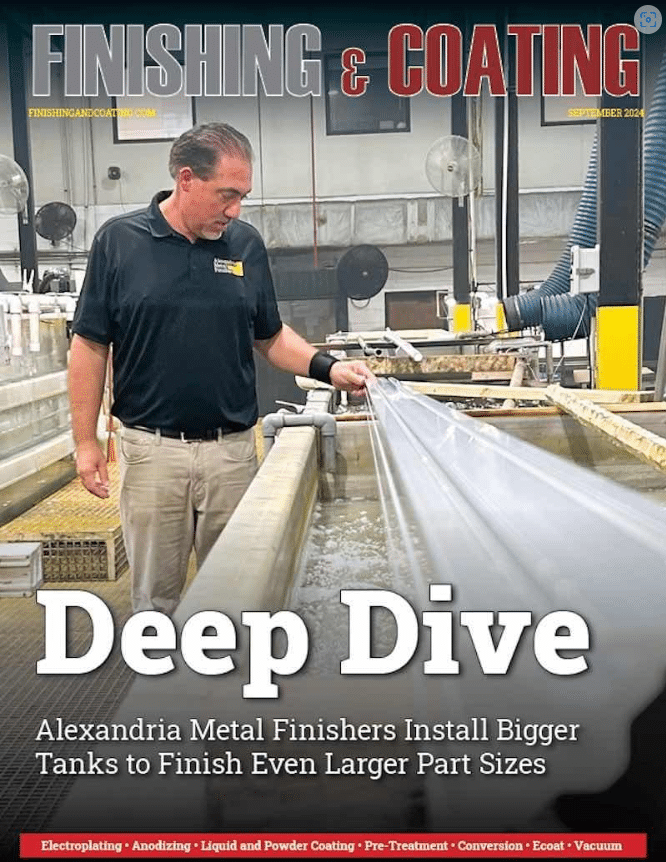

Alexandria Metal Finishers expanded its anodize line capacity to 16′ for anodized Hardcoat Type III and 20′ for Type II with black dye capability for both processes up to 16′.

2024-2025

The electroless nickel, gold, and matte silver lines were expanded and improved for a larger capacity.

The Future of AMF

Alexandria Metal Finishers continues to develop and improve cutting-edge processes for the future and beyond.